In the palm oil processing industry, businesses are constantly faced with challenges such as high production costs, environmental regulations, and the need for high - quality product output. The demand for advanced palm oil refining equipment has been on the rise. Traditional equipment often struggles to meet the requirements of modern production, including efficient processing, energy conservation, and environmental protection. For example, in some small - scale palm oil processing plants, the old - fashioned equipment consumes a large amount of energy and produces a significant amount of waste, which not only increases the production cost but also has a negative impact on the environment.

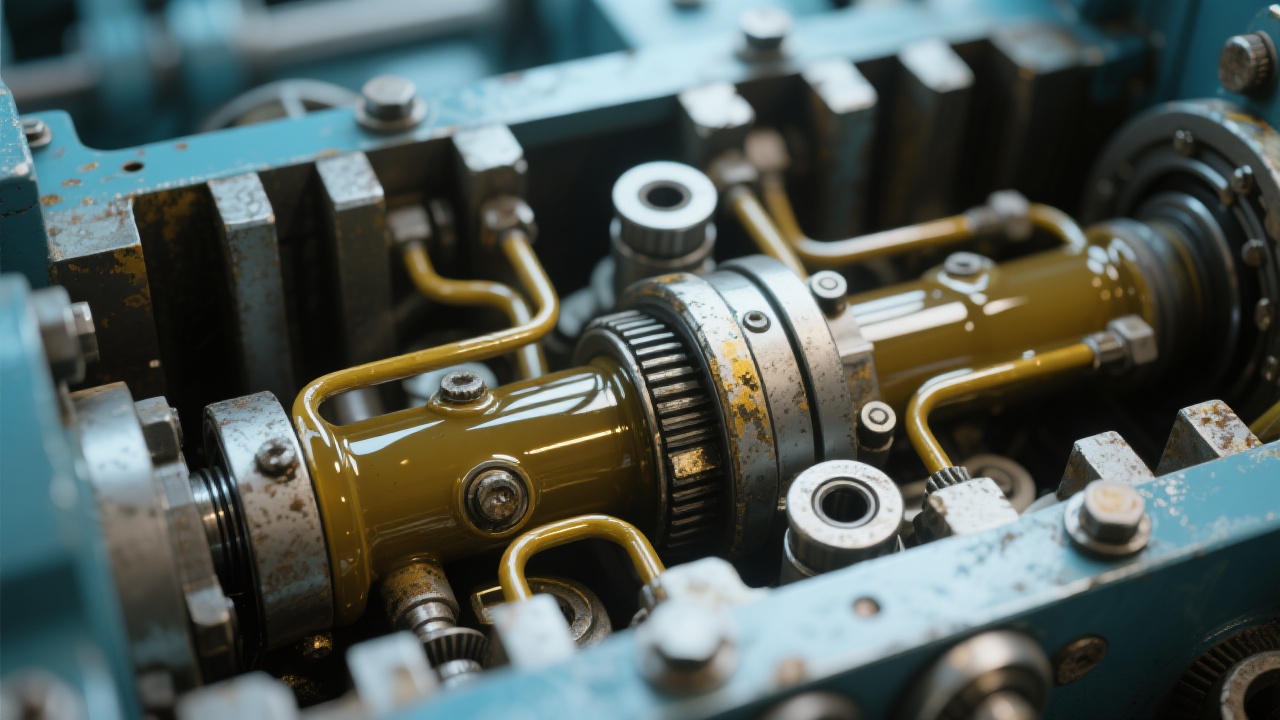

The palm oil refining equipment launched by Penguin Group features advanced leaching and refining processes. In the leaching process, it uses a highly efficient solvent extraction method. The design of the leaching tank ensures a uniform contact between the palm oil raw material and the solvent, which significantly improves the oil extraction rate. For instance, in comparison with traditional leaching methods, the oil extraction rate of this equipment can reach up to 95%, while the traditional ones may only achieve around 90%.

In the refining process, the equipment adopts a multi - stage refining system. It can effectively remove impurities, free fatty acids, and pigments from the crude palm oil. The advanced refining technology can ensure that the refined palm oil meets the high - quality standards required by the market, such as having a low acid value (less than 0.1%) and a light color.

One of the most significant advantages of this palm oil refining equipment is its energy - saving and environmental - friendly design. It is equipped with an advanced fully automatic PLC control system. This system can precisely control the temperature, pressure, and flow rate in each process of the equipment, ensuring the stable operation of the equipment and reducing unnecessary energy consumption.

In terms of energy consumption, the steam consumption per ton of oil is less than 300 kilograms, and the power consumption rate is only 22 kilowatt - hours. Compared with traditional equipment, which may consume more than 500 kilograms of steam per ton of oil and have a power consumption rate of over 30 kilowatt - hours, this equipment can save a large amount of energy costs. For a medium - sized palm oil processing plant that processes 100 tons of palm oil per day, it can save approximately $500 - $800 in energy costs per day.

Moreover, the equipment also has a good environmental protection performance. It has a waste treatment system that can effectively treat the waste generated during the production process, reducing the pollution to the environment. For example, the waste water treatment system can purify the waste water to meet the discharge standards, and the waste residue can be recycled for other purposes, such as being used as organic fertilizer.

With years of experience in the palm oil processing industry, Penguin Group has designed the equipment with high stability and efficiency. The structure of the equipment is made of high - quality materials, which can withstand the long - term operation and the corrosion of the processing environment. The advanced control system also ensures the stable operation of the equipment, reducing the probability of breakdowns. For example, in a large - scale palm oil processing plant in Southeast Asia, the equipment has been running stably for more than 2 years with a breakdown rate of less than 1%.

In terms of efficiency, the equipment can process a large amount of palm oil in a short time. It can complete the leaching and refining processes of 10 - 20 tons of palm oil per hour, which is much higher than the processing capacity of traditional equipment.

Many users have given positive feedback on this palm oil refining equipment. A palm oil processing enterprise in Africa reported that after using this equipment, the production cost has been significantly reduced, and the quality of the refined palm oil has been improved, which has increased their market competitiveness. Another user in South America said that the energy - saving and environmental - friendly design of the equipment is very in line with their local environmental protection requirements, and they are very satisfied with the equipment's performance.

In summary, the palm oil refining equipment launched by Penguin Group brings comprehensive benefits to the palm oil processing industry. Its energy - saving and environmental - friendly design can reduce production costs and meet environmental protection requirements. The advanced technical features ensure high - quality product output and high production efficiency. The stability of the equipment also reduces the maintenance cost and production interruption risk.

If you want to learn more about how this advanced palm oil refining equipment can enhance your business competitiveness, click here to explore further.