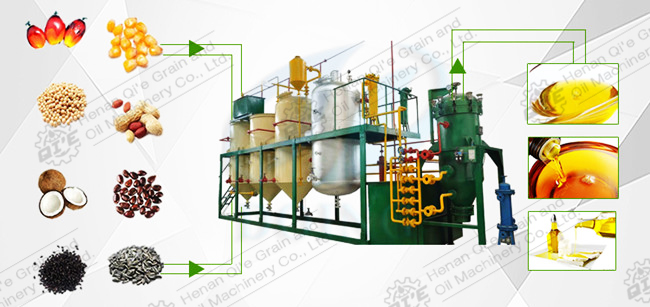

In the palm kernel oil extraction industry, efficiency, quality, and cost - effectiveness are the top concerns for technical leaders and procurement decision - makers in grain and oil processing enterprises. Penguin Group's PLC automated palm kernel oil extraction and refining equipment offers a comprehensive solution to these challenges. Let's delve into the details of this advanced technology.

The design of the PLC automated control system is centered around achieving high - precision control of the palm kernel oil extraction process. It is based on a modular design concept, which allows for easy expansion and customization according to different production requirements. The system uses a hierarchical structure, with a central control unit managing multiple sub - control modules. This design enhances the stability and reliability of the system.

For example, in a palm kernel oil processing plant with a daily production capacity of 100 tons, the PLC system can precisely control the temperature, pressure, and flow rate of each stage of the extraction process. This ensures that the extraction process is carried out under optimal conditions, resulting in high - quality palm kernel oil production.

Sensors are the eyes and ears of the PLC automated control system. They are installed at various key points in the extraction equipment to collect real - time data on parameters such as temperature, pressure, moisture content, and oil quality. This data is then transmitted to the PLC control unit, which analyzes it and makes necessary adjustments to ensure the stability and efficiency of the production process.

For instance, temperature sensors can detect any abnormal temperature changes during the extraction process. If the temperature is too high, the system can automatically adjust the heating power to prevent oil quality degradation. In a case study of a plant with a 50 - ton daily capacity, the use of sensors reduced the rate of sub - standard oil production by 15%.

The intelligent regulation technology of the PLC system is designed to optimize the production process. It uses advanced algorithms to analyze the data collected by sensors and make real - time decisions on process adjustments. This technology can adapt to different raw material qualities and production requirements, improving both production efficiency and product quality.

For example, when dealing with palm kernels of different moisture contents, the intelligent regulation technology can adjust the pre - treatment process in real - time. This ensures that the extraction process is always carried out at the highest efficiency, increasing the oil yield by up to 8% compared to traditional methods.

Penguin Group's PLC automated equipment can be configured to meet different production capacity requirements, ranging from 5 to 500 tons per day. The system's flexibility allows it to adapt to various production scales, whether it is a small - scale local factory or a large - scale industrial plant.

In complex environments, such as high - humidity or high - temperature areas, the equipment shows excellent stability. For example, in a plant located in a tropical region with high humidity, the PLC system can still maintain stable operation, ensuring continuous and efficient production. In fact, in a long - term operation test in a similar environment, the equipment's failure rate was reduced by 20% compared to non - automated equipment.

Automation control has significantly reduced production costs and human intervention in the palm kernel oil extraction industry. In a large - scale palm kernel oil processing plant, the use of Penguin Group's PLC automated system reduced labor costs by 30% and energy consumption by 25%. The system can operate continuously for long periods with minimal human supervision, reducing the risk of human - error and improving overall production efficiency.

Q: Can the system be easily integrated with existing production lines?

A: Yes, the modular design of the PLC system allows for easy integration with existing production lines. Our technical team can provide on - site installation and commissioning services to ensure a smooth integration process.

Q: What is the maintenance requirement for the equipment?

A: The equipment has a low maintenance requirement. The PLC system can perform self - diagnosis and fault alarm functions. Regular inspections and simple cleaning are usually sufficient to keep the equipment in good working condition.

In conclusion, Penguin Group's PLC automated palm kernel oil extraction and refining equipment offers a one - stop solution with advanced technology, high flexibility, and excellent stability. It can significantly improve production efficiency, reduce costs, and enhance product quality. If you are interested in learning more about this technology or need a customized solution for your palm kernel oil processing plant, click here to get more detailed information and technical support.