As industrial sectors worldwide embrace sustainability, the demand for energy-saving and environmentally friendly palm kernel oil refining equipment has surged. This trend is propelled by stringent regulations, rising energy costs, and a growing commitment to sustainable production practices. Within this context, modern refining technologies play a pivotal role in enabling producers to optimize operational efficiency while reducing their environmental footprint.

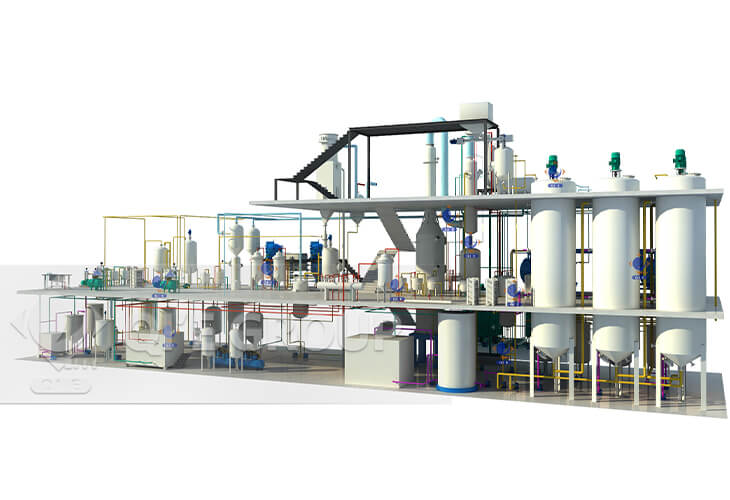

The latest palm kernel oil refining equipment integrates a comprehensive extraction process combined with advanced refining stages, ensuring high-quality output. The system features a multi-step process starting with impregnation, followed by solvent extraction, degumming, neutralization, bleaching, deodorization, and finishing. Such a complete workflow guarantees the production of premium-grade refined oil, meeting rigorous quality standards.

Central to this efficiency leap is the adoption of a fully automated PLC (Programmable Logic Controller) control system. This smart automation precisely regulates temperature, flow rates, and reagent dosing, minimizing process variations and human error. As a result, processing speed improves by approximately 20–30%, while labor requirements reduce noticeably, cutting operational expenses.

Energy consumption constitutes a major operational cost for oil refining facilities. This equipment's design prioritizes energy conservation through optimized heat exchange systems, vacuum technology, and waste heat recovery. An independent industry study observed a 30% reduction in overall energy usage compared to conventional systems, translating to significant cost savings.

| Parameter | Traditional Equipment | Energy-saving Equipment | Improvement |

|---|---|---|---|

| Energy Consumption (kWh/ton oil) | 450 | 315 | -30% |

| Labor Cost Reduction | Baseline | Reduced by 25% | -25% |

| Processing Efficiency (tons/day) | 50 | 65 | +30% |

One notable application of this energy-saving technology was within a leading palm kernel oil refinery in Southeast Asia. Prior to adopting the new equipment, the facility grappled with high energy bills and inconsistent oil quality. After installation, the refinery reported:

This successful green upgrade not only yielded enhanced profitability but also positioned the enterprise as an industry leader in sustainable production, garnering positive stakeholder recognition.

In a competitive global market, investing in energy-efficient palm kernel oil refining equipment ensures operational resilience and compliance with increasingly strict environmental standards. This equipment’s automation and energy conservation features not only reduce costs but also equip companies for future regulatory landscapes and customer demands for eco-conscious products.

Furthermore, the scalable design enables integration into both small and large-scale facilities, offering flexibility and customization for various production capacities.

Contact us today for a tailored consultation and see firsthand how efficiency and sustainability boost your bottom line.

Learn More & Request a Demo