Palm oil processing enterprises often encounter various challenges in their production processes. These include high production costs, low efficiency, and environmental concerns. For instance, traditional refining methods may consume a large amount of energy, with an average energy consumption of up to 800 kWh per ton of palm oil processed. Additionally, the error rate in manual operation can be as high as 10%, leading to inconsistent product quality and increased waste.

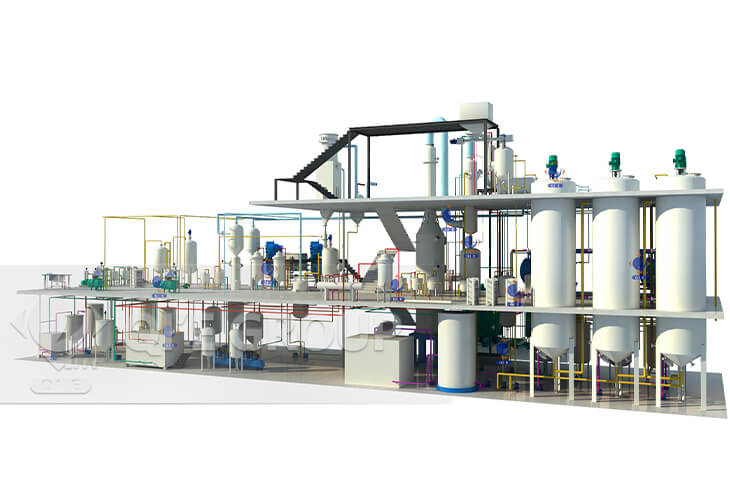

The palm crude oil refining equipment provided by Penguin Group has a complete set of leaching and refining processes. This integrated design ensures that every step of the palm oil production, from the extraction of crude oil to the final refined product, is carried out smoothly. Compared with traditional equipment, it can increase the oil extraction rate by 15%. That is, for every 100 tons of palm fruit, an additional 15 tons of oil can be obtained.

Equipped with a fully automatic PLC control system, this equipment offers great convenience in operation. The system can precisely control various parameters such as temperature, pressure, and flow rate during the refining process. The error rate is reduced to less than 1%, which is far lower than the 10% error rate of manual operation. This not only improves product quality but also saves a lot of labor costs.

In terms of energy consumption, the new equipment is highly efficient. It can reduce energy consumption by 30% compared with traditional equipment. The average energy consumption per ton of palm oil processed is only about 560 kWh. Moreover, it produces less waste and pollution during the production process, meeting the strict environmental protection requirements.

From the perspective of palm oil processing enterprises, using this advanced equipment can bring many benefits. Firstly, the increased oil extraction rate directly leads to higher production volume and more profits. Secondly, the low error rate and high - quality products enhance the enterprise's market competitiveness. Thirdly, the energy - saving and environmental - friendly features help the enterprise to meet environmental regulations and reduce long - term operating costs.

A well - known palm oil processing enterprise in Malaysia has adopted this palm crude oil refining equipment. After using the equipment for one year, its production cost has been reduced by 25%. The product quality has also been significantly improved, and it has successfully expanded its market share in the international market. Another enterprise in Indonesia has seen a 30% increase in its production efficiency after replacing the old equipment with this new one.

Don't miss out on the opportunity to enhance your production efficiency, reduce costs, and boost your competitiveness in the market. Contact us today to learn more about our high - efficiency palm crude oil refining equipment and take the first step towards a more profitable future!