Are you looking to produce high - quality palm kernel oil efficiently? This article will guide you through the process of selecting and installing palm kernel oil production equipment, with a focus on practicality and professionalism.

When it comes to palm kernel oil production equipment, the production capacity is a crucial factor. 5 - 500 tons per day. Each capacity range has its own core configuration logic. For example, for a small - scale production line with a capacity of 5 - 50 tons per day 20 tons per day, a relatively simple and compact extraction system may be sufficient. a small - scale expeller < 20 tons per day. For a medium - scale production line with a capacity of 50 - 200 tons per day, more advanced and automated equipment is required. A case in point is a palm kernel oil production plant in Malaysia, which increased its production efficiency by 30% after upgrading its equipment according to the capacity - based configuration logic.

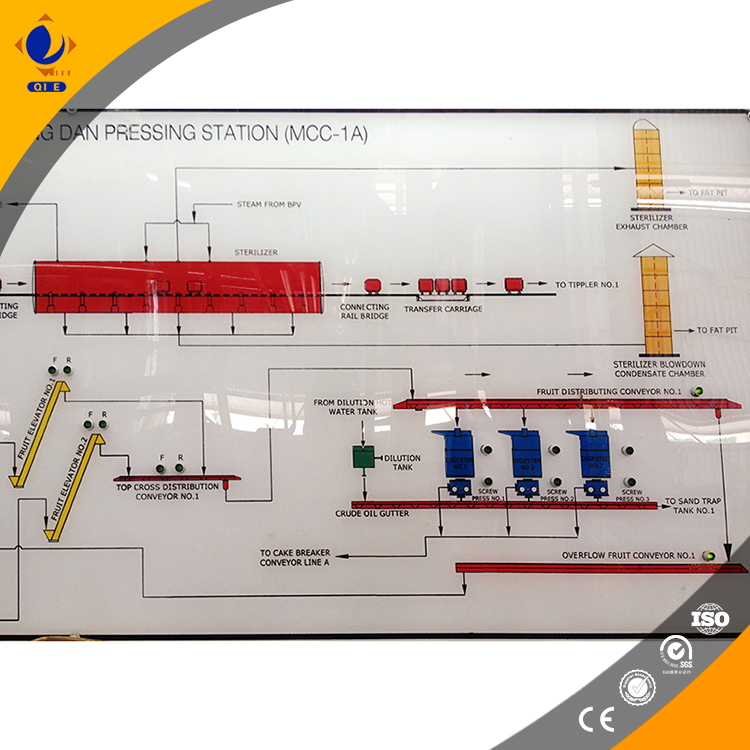

The installation stage is equally important. First, the on - site environment requirements are strict. The installation site should be dry, well - ventilated, and have a flat ground. The pipeline layout should be scientific to ensure smooth material flow. For example, the distance between pipelines should be no less than 0.5 meters to avoid interference. Electrical safety is also a top priority. All electrical components must meet CE/ISO certification standards to ensure long - term stable operation.

During the debugging period, problems such as pressure fluctuations and abnormal solvent recovery may occur. For pressure fluctuations, it may be caused by blockages in the pipeline or improper valve settings. You can check the pipeline for blockages and adjust the valve opening. For abnormal solvent recovery, it may be due to issues with the solvent recovery system. Regularly checking the condenser and separator can prevent such problems.

To ensure the long - term stable operation of the equipment, a daily inspection checklist, regular maintenance plan, and fault response mechanism are essential. The daily inspection should include checking the equipment's appearance, temperature, and pressure. A monthly maintenance plan should be formulated to lubricate moving parts and check the tightness of bolts. In case of equipment failure, a 24 - hour response mechanism should be established to minimize downtime.

Your equipment is a key factor in the success of your palm kernel oil production. Is your equipment meeting these standards? Leave a message and tell us!

Choose Penguin Group, and you're not just buying equipment; you're getting a complete production support system. Our professional team will provide you with comprehensive solutions from equipment selection to after - sales service. Don't miss this opportunity to enhance your palm kernel oil production efficiency.

Click here to learn more about our palm kernel oil production equipment!