Palm kernel oil production demands robust and precisely tailored equipment solutions to ensure operational efficiency, safety, and longevity in a competitive global market. This guide unfolds the critical technical and managerial aspects of selecting, installing, and maintaining palm kernel oil production equipment spanning capacities from 5 to 500 tons per day. Drawing on up-to-date industry standards and field expertise, it positions manufacturing operators to optimize output while minimizing downtime and maintenance costs.

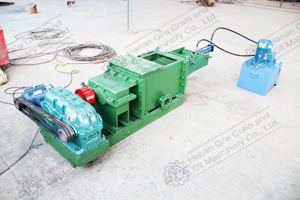

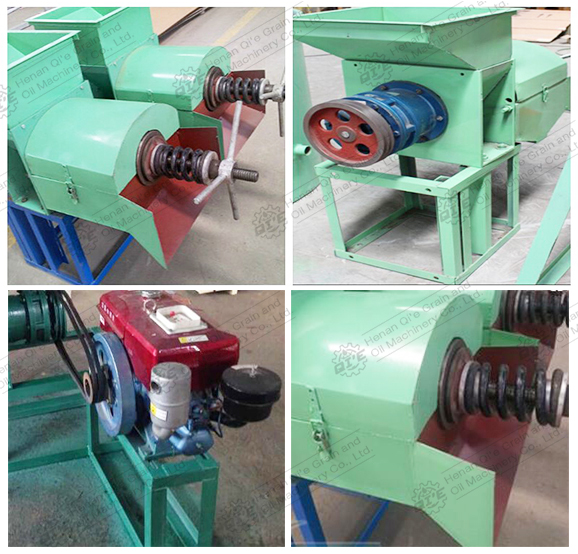

Choosing the correct machinery depends heavily on your specific production scale, raw material characteristics, and desired product quality. For small to medium-scale plants (5-50 tons/day), modular screw presses combined with solvent extraction units offer flexible, cost-effective solutions with quick scalability. Medium to large plants (50-200 tons/day) benefit from integrated automatic hydraulic presses paired with continuous filtration systems that improve yield and reduce oil oxidation. For large-scale operations (200-500 tons/day), fully automated extraction and refining lines featuring PLC (Programmable Logic Controller) systems ensure maximum throughput with consistent quality control.

| Capacity (tons/day) | Recommended Equipment Type | Key Features |

|---|---|---|

| 5 - 50 | Modular Screw Press + Solvent Extraction | Flexible startup, low CAPEX, easy maintenance |

| 50 - 200 | Automatic Hydraulic Press + Continuous Filter | Higher yield, reduced labor, enhanced oil quality |

| 200 - 500 | Fully Automated Extraction & Refining Line with PLC Control | Max throughput, tight process control, minimal downtime |

Proper installation is fundamental to equipment longevity and safe operation. The installation site must provide stable foundations capable of supporting equipment loads up to 1.5 times design weight to prevent vibrations that degrade machinery precision. Ambient temperature and humidity should remain within manufacturer specified ranges (typically 15°C to 35°C and below 70% relative humidity).

Critical installation parameters include:

Strict adherence to these technical and safety standards mitigates risks and enhances production reliability.

Early operation phases often reveal issues that, if unaddressed, can cause expensive downtime or physical damage. Common equipment malfunctions include:

| Issue | Cause | Recommended Action |

|---|---|---|

| Low Oil Yield | Improper press pressure or kernel moisture content | Calibrate pressure settings; control raw material quality |

| Excessive Vibration | Uneven mounting or imbalance in rotating parts | Re-align foundation bolts; balance rotating assemblies |

| Overheating Motors | Electrical faults or insufficient cooling | Inspect electrical connections; verify cooling systems |

Close collaboration with technical support teams during commissioning accelerates problem resolution and sets a foundation for long-term success.

Consistent maintenance is essential to prevent unplanned failures and maximize equipment lifespan. A robust maintenance strategy includes:

Implementing maintenance management software can automate scheduling, logging, and reporting, offering predictive insights that reduce downtime by up to 30%, as per industry benchmarks.

Engaging trained personnel and aligning with OEM recommendations ensures adherence to quality and safety standards such as ISO 9001 and ISO 50001 energy management.

Q1: What is the typical lifespan of palm kernel oil production equipment?

With proper maintenance, key components typically last 10-15 years, while periodic refurbishments can extend equipment life beyond 20 years.

Q2: How can I optimize energy consumption during operation?

Utilize variable frequency drives for motors, schedule operations during off-peak energy hours, and maintain equipment to reduce friction losses.

Q3: Are there environmental compliance requirements related to equipment operation?

Yes, adherence to local emissions standards, proper waste oil handling, and implementation of closed-loop solvent systems are critical for sustainable production.

Investing in high-quality, well-maintained palm kernel oil production equipment translates into substantial long-term savings through enhanced extraction rates, lower energy consumption, and reduced repair costs. Partnering with a supplier offering turnkey solutions—including equipment supply, installation oversight, staff training, and continuous technical support—further ensures seamless operation and competitive advantage.