Are you looking for the most suitable equipment configuration for your palm kernel oil production project? This article provides a detailed analysis of the best equipment selection solutions for different production capacities ranging from 5 to 500 tons per day. Whether your business is operating in Asia, Africa, or South America, our equipment from Penguin Group can help you achieve a residual oil rate of ≤1% and a solvent consumption of ≤2kg/T, ensuring efficient and stable operation.

We understand that different production scales require different equipment combinations. For small - scale workshops with a capacity of 5 tons per day, a more compact and cost - effective equipment configuration is recommended. On the other hand, large - scale factories with a capacity of 500 tons per day need high - efficiency and fully automated equipment.

Here is a comparison table of equipment configurations for different production capacities:

| Production Capacity (Tons per Day) | Key Equipment | Advantages |

|---|---|---|

| 5 | Small - scale extraction units, basic refining equipment | Low investment, suitable for startups |

| 500 | Large - scale automated extraction lines, advanced refining systems | High efficiency, large - scale production |

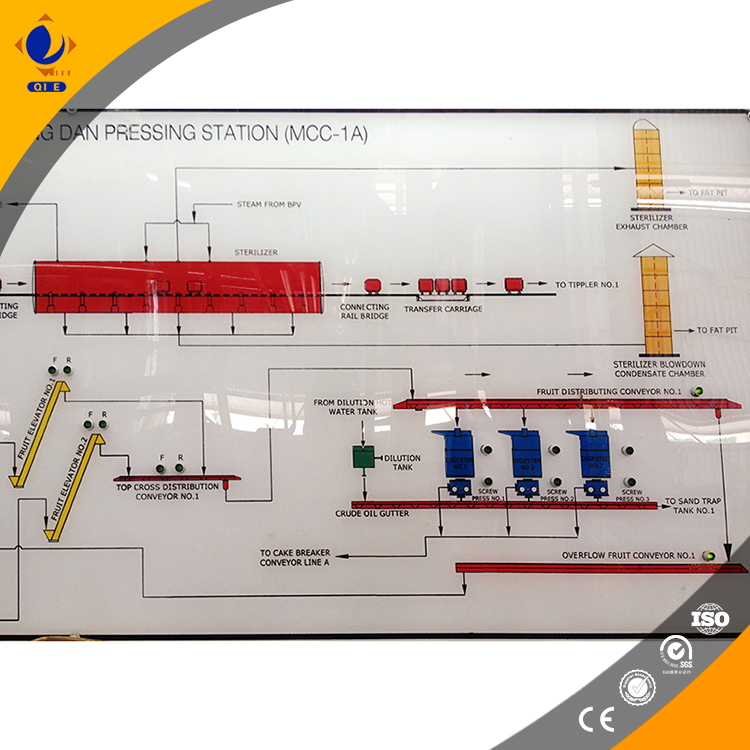

Our equipment meets international certification standards such as CE, ISO9001, and BV. Key components like motors, pressure vessels, and PLCs have undergone strict testing processes. This ensures the reliability and compliance of our equipment, giving you peace of mind in your production process.

During the installation phase, several technical details need to be considered. The on - site environment should be clean, dry, and well - ventilated. The equipment layout should be reasonable to ensure smooth material flow. Pipeline connections must follow strict specifications, and electrical safety protection measures are essential. We also provide comprehensive personnel training to ensure that your staff can operate the equipment correctly.

During the debugging period, some common problems may occur, such as system instability, low solvent recovery efficiency, and excessive residual oil. We have a set of practical troubleshooting steps and solutions. For example, if the solvent recovery efficiency is low, we can check the solvent recycling system step by step to find and fix the problem.

We share industry - leading operation and maintenance experience. A full - cycle management system from daily inspections, fault prevention to regular maintenance can be established. This helps to extend the service life of the equipment and ensure continuous production.

Q: What is the residual oil rate of your equipment?

A: Our equipment can achieve a residual oil rate of ≤1%.

Q: How about the solvent consumption?

A: The solvent consumption is ≤2kg/T.

Our palm kernel oil production equipment is your best choice in the grain and oil processing field. It can help you easily achieve stable and efficient production goals. Don't miss this opportunity to enhance your long - term profitability and reduce investment risks. Click here to learn more.