When setting up a palm kernel oil production line—from small-scale 5-ton/day operations to large industrial facilities processing up to 500 tons per day—many buyers overlook critical details during equipment selection, installation, and commissioning. These oversights can lead to inefficiencies that cost thousands in lost output and unexpected downtime.

According to industry benchmarks, companies that match their equipment capacity with actual production needs see an average 27% higher throughput in the first six months compared to those who over- or under-specify. For example, choosing a screw press designed for 100 tons/day when your facility runs at only 20 tons/day leads to poor mechanical efficiency and increased wear on bearings and gears.

| Production Capacity (tons/day) | Recommended Equipment Type | Key Consideration |

|---|---|---|

| 5–20 | Manual/semi-auto hydraulic press + batch solvent extraction | Low maintenance, easy training for local staff |

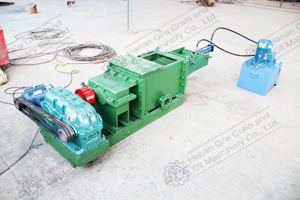

| 50–200 | Continuous screw press + automated solvent recovery system | Energy-efficient, scalable for future growth |

| 300–500 | Fully integrated plant with PLC control & real-time monitoring | Minimizes labor dependency, maximizes yield consistency |

Even with perfect equipment choice, improper installation causes nearly 40% of initial failures reported by global clients. The most frequent issues include:

Our technical team recommends conducting a pre-installation site audit using our free checklist—used successfully by over 200 clients across Southeast Asia, Africa, and South America—to reduce commissioning delays by up to 6 weeks.

During the first week of operation, watch out for these red flags:

We’ve compiled a comprehensive troubleshooting guide based on 3+ years of field data from our clients worldwide. It includes step-by-step videos, error codes, and contact protocols for immediate support.

At Penguin Group, we don’t just deliver machines—we ensure you run them right from Day One. Our engineers provide remote diagnostics, on-site training, and ongoing performance reviews tailored to your location’s climate, workforce skill level, and raw material quality.