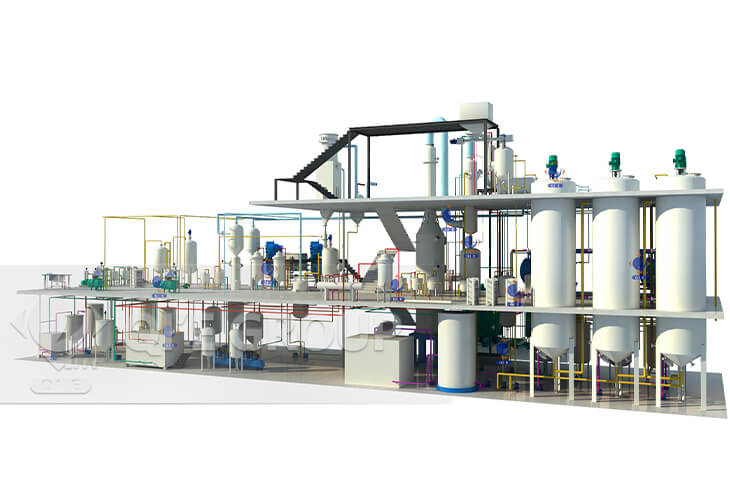

In the global palm oil processing industry, market competition is intensifying. Obtaining high - quality palm oil products efficiently is crucial for enterprises to gain a competitive edge. The reliability and efficiency of equipment play a key role in palm oil processing. High - efficiency and stable equipment can not only improve production efficiency but also ensure product quality stability, which is an indispensable factor for enterprises to achieve sustainable development. Among the many palm oil processing equipment providers, Penguin Group's palm crude oil refining equipment stands out with its advanced technology and excellent performance.

Penguin Group's palm crude oil refining equipment adopts a complete leaching process. This process can effectively extract palm oil from palm fruits. Through scientific design and strict control of process parameters, the utilization rate of raw materials is greatly improved. For example, in large - scale palm oil processing plants, the oil extraction rate can reach over 95%, which ensures high - yield production and reduces production costs per unit of the product.

After the leaching stage, the palm oil undergoes a series of refining procedures. These procedures include degumming, deacidification, decolorization, and deodorization. Each step precisely controls key factors such as temperature, pressure, and time to ensure high - quality refined palm oil products. For instance, the acid value of the refined palm oil can be reduced to less than 0.1mg KOH/g, fully meeting international quality standards.

One of the highlights of this equipment is the advanced fully automatic PLC control system. This system enables real - time monitoring and precise control of each link in the production process. Workers can operate through a simple touch - screen interface, greatly reducing the labor intensity and potential errors caused by manual operations. Moreover, the system can store historical production data, facilitating enterprises to analyze production processes and optimize equipment performance.

In terms of energy efficiency, Penguin Group's palm crude oil refining equipment has outstanding performance. The steam consumption per ton of oil is less than 300 kilograms, and the power consumption per ton of oil is only 22 kilowatt - hours. These data demonstrate that the equipment not only saves a large amount of energy but also reduces production costs for enterprises. In addition, the equipment pays attention to environmental protection in the design process. It adopts advanced waste treatment technology to minimize the environmental impact caused by production.

Assume an enterprise purchases Penguin Group's palm crude oil refining equipment. After a period of use, enterprises find that production efficiency has been significantly improved, and product quality has become more stable. The labor cost has also been reduced due to the automated control system. At the same time, energy - saving and environmental - friendly design has not only reduced production costs but also enhanced the enterprise's social image. Users generally express satisfaction with the performance of the equipment and are willing to recommend it to other enterprises.

In summary, Penguin Group's palm crude oil refining equipment combines advanced technology, high - efficiency production, energy - saving, and environmental protection. Whether it is the complete process flow, the precise control of the automated system, or the excellent performance in energy - saving and environmental protection, it can provide enterprises with comprehensive palm oil processing solutions. If you are interested in our palm crude oil refining equipment and want to learn more about its features, technical parameters, and cooperation modes, please do not hesitate to contact us. Our professional team will provide you with detailed information and high - quality services.

Contact us today and take the first step towards efficient palm oil processing!