Navigating the diverse demands of palm kernel oil production requires equipment tailored precisely to your processing capacity. From small-scale operations at 5 tons per day to large industrial setups reaching 500 tons per day, choosing the right equipment configuration is critical to ensuring operational efficiency, product quality, and investment value. This guide systematically unpacks the selection criteria, installation standards, commissioning challenges, and maintenance strategies that underpin high-performance palm kernel oil production — offering you a comprehensive roadmap for optimal decision-making.

Equipment configuration for palm kernel oil production varies significantly across scales. Here are typical technical parameters aligned with daily production capacities:

| Daily Capacity (tons) | Pressing Unit Power (kW) | Extraction Yield (%) | Automation Level |

|---|---|---|---|

| 5 - 20 | 45-90 | 40-45% | Semi-Automatic |

| 20 - 100 | 90-200 | 45-50% | Fully Automatic |

| 100 - 500 | 200-600 | 50-55% | Fully Automatic with Integrated Control System |

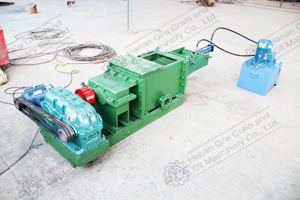

Modern palm kernel oil equipment integrates high-efficiency hydraulic pressing and solvent extraction to maximize yield while minimizing energy consumption. Quality certifications such as ISO 9001 and CE reinforce operational reliability and safety compliance.

Proper installation sets the foundation for equipment longevity and safe operation. Key considerations include:

Thorough pre-installation site assessment and adherence to technical guidelines reduce installation-related risks and downtime.

The commissioning phase commonly encounters issues that, if unaddressed, could degrade performance:

Regularly engaging qualified technicians during commissioning optimizes uptime and accelerates production ramp-up.

Maximizing equipment lifespan and ensuring sustained high output depend on disciplined management:

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Daily Visual Inspection | Every operational day | Detect leaks, unusual noises, and wear |

| Lubrication of Moving Parts | Weekly | Reduce friction and prevent equipment failure |

| Electrical and Sensor Check | Monthly | Ensure accuracy and prevent control failures |

| Major Overhaul | Every 12 months | Replace worn components and recalibrate systems |

Deploying IoT sensors and automated alert systems can further enhance preventive maintenance efficacy, reducing unplanned downtime by up to 25%.

Ready to enhance your palm kernel oil production with high-reliability, expertly configured equipment? Discover Penguin Group’s Full Lifecycle Service and Technical Support Today — your partner in maximizing operational efficiency and investment returns.